No compromise on position, speed and torque!

We have acquired the ability to accurately execute the control elements required

by our customers with the latest technology.

Features

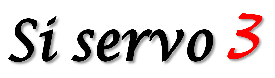

1. Si servo3 has lineup of 9 types of motors.

We have motors from 0.05N to 2.0N type.

We have newly added 0.7N type / 0.8N type motors to our lineup.

In addition, in the Si servo 3 series, we have standardized motors with characteristics that cause little torque reduction even in the high speed range.

In general stepping motors, torque reduction in the high speed range is a problem, but Si servo 3 outputs sufficient torque even in the high speed range and realizes high tact operation.

We have newly added 0.7N type / 0.8N type motors to our lineup.

In addition, in the Si servo 3 series, we have standardized motors with characteristics that cause little torque reduction even in the high speed range.

In general stepping motors, torque reduction in the high speed range is a problem, but Si servo 3 outputs sufficient torque even in the high speed range and realizes high tact operation.

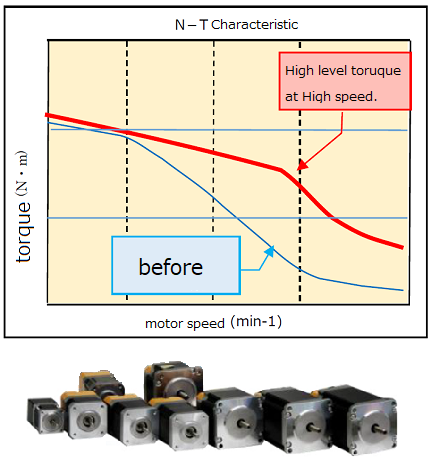

2. Super high speed motor that rotates at a maximum of 6000 rpm.

With a general stepping motor, the limit is about 3000 rpm to 4000 rpm, and the output torque in this rotation range was not at a practical level.

In Si servo3, we have added a motor that can be practically used up to 6000 rpm in the 0.3N type to the lineup.

In Si servo3, we have added a motor that can be practically used up to 6000 rpm in the 0.3N type to the lineup.

3. Equipped with a high resolution encoder.

All models are equipped with a 10,000 pulse / rev encoder.

Highly accurate feedback of position information and speed information realizes highly accurate positioning and smooth operation without attachment and detachment.

It has the ability to generate up to 200% torque depending on the deviation of the feedback.

Highly accurate feedback of position information and speed information realizes highly accurate positioning and smooth operation without attachment and detachment.

It has the ability to generate up to 200% torque depending on the deviation of the feedback.

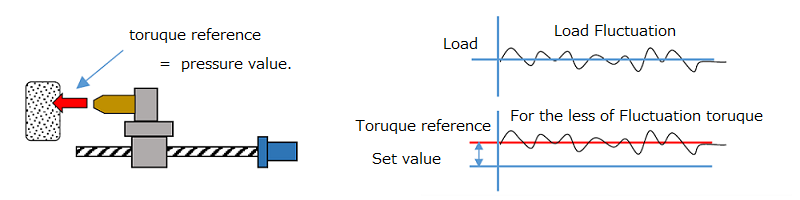

4. NEW function was developed [Toruqe research]!

Various linear motion mechanisms are affected by mechanical load fluctuations, and it is not possible to control accurate pressing force only by torque limiting.

With Si servo 3, you can control the exact pressure by learning the load without using feedback such as sensors.

In addition, fine pressure adjustment is also possible.

With Si servo 3, you can control the exact pressure by learning the load without using feedback such as sensors.

In addition, fine pressure adjustment is also possible.

Specifications

Driver specifications

| Models | Si-02DT | Si-05DT | |||

|---|---|---|---|---|---|

| Application motor |

SM-L5MT SM-02MT SM-03MN SM-04MT SM-07MT SM-08MT SM-09MT |

SM-12MT SM-20MT |

|||

| Rated output current (A0-p) | 3 | 5 | |||

| Maximum output current (A0-p) | 6 | 10 | |||

| Control mode |

Servo contorol mode / Stepping motor control mode Select for Parameters |

||||

| Control method | Transistor PWM (sine wave drive) | ||||

| Allowable load inertia | 20 times of motor inertia | ||||

| Feedback |

Incremental encoder 1:10000 (Si servo2 motor 1:800 or 1:1600) |

||||

|

Outline dimensions (mm) [not include the protrusion] |

39(W) × 70(H) × 55(D) | 42.2(W) × 76(H) × 85(D) | |||

| Outline Mass (kg) | 0.1 | 0.19 | |||

|

Power supply (V) |

Motor supply | DC24V±10% | |||

| Control supply | |||||

|

Rated current (A) |

Motor current | 2.8A | 4.0A | ||

| Control current | 0.05A | 0.05A | |||

|

Maximum power current (A) |

Motor Current | 4.0A | 5.0A | ||

| Control current | 0.1A | 0.1A | |||

| Position command system |

3 mode pulse signal, and communication by RS485, the point table with DI/DO. |

||||

| Operating temperature | 0 ~ +50 ℃ | ||||

| Storage temperature | -20 ~ +85 ℃ | ||||

| Operation and storage humidity | Less than 90% RH (non-condensing) | ||||

| Vibration resistance | 0.5G | ||||

| Shock resistance | 2G | ||||

| Input signal |

5 points (select a function by parameter) Photo coupler DC30V Max. |

||||

| Command pulse input |

CW/CCW、PULSE/SIGN、A / B-phase input(selected by parameter). 5V line-driver (26C31 equivalent). 5V・24V open-collector to photo-coupler. |

||||

| Maximum response frequency |

line-driver:750kpps / open-collector:200kpps (When duty cycle rate 50%) |

||||

| Output signal |

3 numbers.(select by parameter). open-collector DC30V Max. / 50mA |

||||

| Brake unlock signal | Dry contact relay DC60V Max. / 1A | ||||

| Encoder signal output | Z-phase only | ||||

|

Protect Alarm |

EEPROM Alarm / Motor EEPROM Alarm / Encorder Alarm / System Abnormal / Position deviation Alarm / A-phase over load / B-phase over load / Temperature Abnormal / Over load / Over voltage / Lower voltage / Control power supply Abnormal |

||||

| Some number Axis control |

RS485 multi-drop connection or USB-HUB connection Setting parameter by the meintenance software. |

||||

| Connection port |

RS485 × 1ch (Baurate:115kbps) / USB 1.1ch × 1ch (Full-Speed Function) Caution) USB can't be use for main controler connection. |

||||

| Command | Broadcast command for grouped groups. | ||||

| Standards and environmental compatibility | CE (Self-declaration) / RoHS2 | ||||

Options

| NAME | TYPE(@@ is LENGTH) | LENGTH(m) |

|---|---|---|

| Motor power cable

For Si-02DT |

Si3-MCB@@M (*1) | 3,5,10 |

| Motor power cable

For Si-05DT |

Si-MCBHC@@M | 3,5,10 |

| Encorder cable | Si3-ECB@@M (*2) | 3,5,10 |

| Power supply cable for AMP.

For Si-02DT |

Si-PWBC@@M | 3 |

| Power supply cable for AMP.

For Si-05DT |

Si-PWBHC@@M | 3 |

| I/O cable | Si-IOB@@M | 3 |

| Regeneration cable | Si-RGVC | 1 |

| RS485 Master unit cable | Si-RSM@@M | 3 |

| Brake cable | Si-BRK@@M | 3 |

| RS485 strate cable | Si-RSS | 0.5 |

*1 If you connect Si2 motor, then select to Si-MCB@@M.

*2 If you connect Si2 motor, then select to Si-ECB@@M.

About the order

Orders and inquiries of this product, please contact Sanmei Co., Ltd.

Sanmei Co., Ltd. Website

Sanmei Co., Ltd. Website