Features

1. PLC + Motion Engine + HMI = Typhoon10!

The Typhoon10 is equipped with PLC functionality, Sanmei's original motion engine, a touch panel LCD display, and the ability to run Windows application software equivalent to a standard PC.

This all-in-one controller can handle sequence control, I/O control, motor axis control, man-machine interface processing, and even IoT terminal processing via internet connection, all in one unit.

2. Robustness that can withstand harsh factory automation environments

The Typhoon10 has a hard disk-less and fan-less structure, ensuring stable durability even in harsh factory automation environments.

Hard disk-less design ensures safety even in vibration environments!Fan-less design improves ease of maintenance and reduces power consumption.

3. High-definition screen display with wide LCD

While the external dimensions are the same as the previous model, the LCD screen has been expanded to 12.1W.

It provides high-resolution screen display of up to 1920 x 1080 pixels.

4. HMI / motion software development in a Windows environment

Typhoon10 is equipped with Windows 10 IoT Enterprise 2021 LTSC.

Application software can be built using a development environment common to standard PCs,

such as Microsoft Visual Studio, making it easy to utilize software design assets.

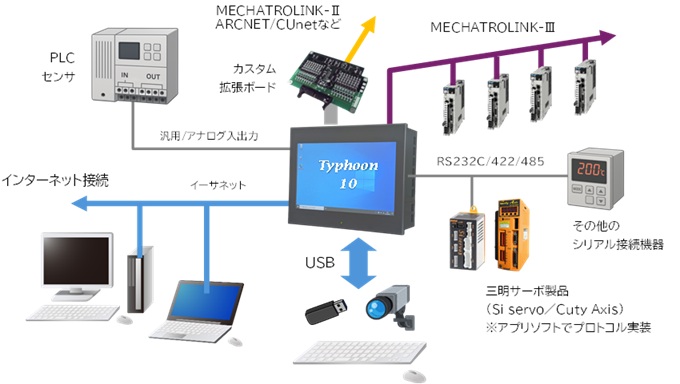

5. Simple, wire-saving and high-speed communication

MECHATROLINK-Ⅲ is installed as a standard field network, achieving high-speed communication with a minimum transmission cycle of 0.5 msec.

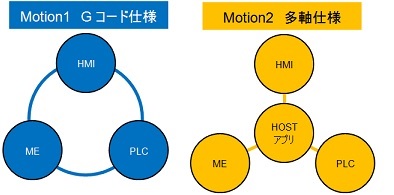

6. Equipped with two types of motion engines

We offer a G-code specification suitable for systems with 6 or fewer servo axes, and a multi-axis specification suitable

for controlling 7 or more servo axes. You can select the specifications that best suit your needs.

7. Various peripheral connection interfaces

In addition to the Ethernet and USB ports found on most PCs, Typhoon10 also supports motor control via

RS232/422/485 serial communication. Additionally, other interfaces are available with custom expansion boards.

Specifications

Basic Specifications

| Specifications |

| Ambient temperature |

Operation temperature |

0 to 50℃ |

| Storage temperature |

-20 to 70℃ |

| Humidity |

10 to 85 ℃ RH or less (no condensation) |

| Power supply |

AC85V to 264V

|

| Atmosphere |

Without corrosive gas, dust or the like |

| Cooling |

Natural air cooling |

Functional specifications

| Specifications |

| CPU |

Intel Celeron N3350 1.1GHz |

| OS |

Windows 10 IoT Enterprise LTSC 2021 (Japanese version) |

| Memory |

eMMc |

64GB |

| LPDDR4x-3200 |

4GB |

| Display |

TFTpanel |

| Touch panel |

Analog method, Resolution: 12 bit |

| Calendar Clock |

Dedicated battery: lithium battery (CR2032) ± 2 minutes / month |

| Audio |

Buzzer output |

| Interface |

Field Network |

Mechatrolink-Ⅲ |

| Ethernet |

1000BASE-T (1 port) |

| USB |

USB2.0 host (1 ports)

Correspond only to storage class

|

| Serial |

RS232C / RS422, 485 (select with switch) |

| Expansion bus |

Mounting × 1 option board (private bath) |

| General-purpose I/O port |

Rated voltage |

24V±5% |

| Input |

Number |

8 (photo coupler) |

| Input current |

5mA |

| OFF voltage |

5V and below |

| Output |

number |

8 (photo coupler) |

| Maximum load |

50mA |

Motion specifications

| Specifications |

| Maximum number of control axes |

16 axes |

| Transmission cycle |

0.5msec, 1msec, 2msec, 4msec |

| Command system |

Position command, speed command, torque command, inverter instruction |

| Feed |

Positioning, linear interpolation (simultaneous 16 axes), circular interpolation (select 2 axes)

Helical interpolation JOG, homing, manual pulser (2CH) |

| Command unit |

Pulse |

| Maximum command value |

± 2147483647 |

| Speed command unit |

pulse / sec |

| Acceleration and deceleration function |

Linear, asymmetric, S-shaped, index |

| Correction function |

Backlash compensation, pitch error correction |

PLC specifications

| Specifications |

| Program method |

Relay symbol system |

| Input-output control system |

Refresh method |

| Program memory |

FLASH ROM |

| Program capacity |

65000 steps |

| Arithmetic processing speed |

Basic instruction 0.5μs / step |

| Constant scan |

1-500ms |

| Basic instruction |

24 types |

| Application Instructions |

83 types |

| Input (X) |

1024 (X0 to X63F) |

| Output (Y) |

1024 (Y0 to Y63F) |

| Internal relay (M) |

16000 (M0 to M999F) |

| Indirection register (Z) |

8 (Z0 to Z7) |

| Special relay (E) |

from E200 |

| Timer (T) |

1024 (T0-T1023)

Low speed (1000ms), medium speed (100ms), high speed (10ms) |

| Counter (C) |

1024 (C0 to C1023), 16-bit up counter |

| Data register (D) |

14000 words (D0 to D13999) |

System reserved area

D14000 to D14999: user input area

D15000 to D15999: user output area |

| Master Control Relay (MC) |

8 |

| Battery backup |

Data register, internal relay and counter area are set by the parameter.

(It requires a external backup battery.) |

* The contents of this specification are subject to change without prior notice for product improvement.