History

We became independent from the technical department in Sanmei Co., Ltd., and established a company capitalized at 3,000,000 yen as "Sanmei engineering Co., Ltd.".

We made a contract with Yakukawa Electric Corporation as a satellite factory, and started operation as a subcontract factory.

Sanmei squid machine was developed.

Transistor servo drive unit was developed.

4-bit computerized numerical control was developed.

8-bit computerized numerical control was developed.

The Company name was changed to "Sanmei Electronics Co., Ltd.".

Head Quarters Building was built and we moved there. (2-2-1 Seikai, Shimizu Ward, Shizuoka City)

Microcomputer-controlled Squid fishing machine was developed.

Versatile 3-axis CNC "PTM-3" was developed.

Custom NC series was developed for the original equipment manufacturing.

The factory building was constructed next to the Head Quarters building.

General-purpose computerized numerical control "PTM-3000" was developed.

We established Tokai Solution Center jointly with Yaskawa Electric Corporation.

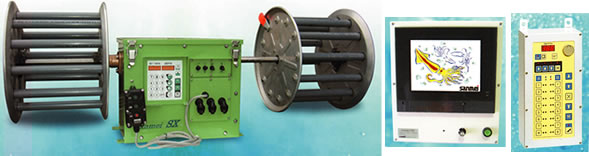

AC servo specification multipurpose fishing machine "SE-30" was developed.

Factory LAN was introduced.

Printed circuit board development system was introduced.

16-bit general-purpose CNC "PTM-4000" was developed.

AC servo "TRB-350" was developed.

Mini servo series was developed.

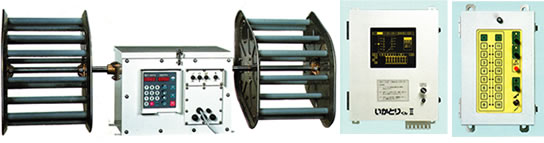

Panel computer specification squid fishing machine "IKATORIKUN II" was developed.

Small AC servo "Cuty Axis" was developed.

Computer NC "CYCLONE" was developed.

The administration building was constructed.

Kiyoji factory (Sanmei Technica) was built.

Small AC servo "Cuty Axis II" was developed.

Panel computer specification squid fishing machine "IKATORIKUN 2000" was developed.

ISO 9001 certification acquisition (We turned down the authentication in December 2003.)

Power optimization analysis system "Eco-Bright" was developed.

FA controller "Typhoon" loaded with the Windows CE was developed.

Stepping servo system "Si servo" was developed.

Kiyoji 2nd factory was constructed.

Si Cuty was serialized and developed.

ISO14001 certification acquisition

Sheet metal equipment state-of-the-art "turret punch press system EMZ" was introduced to Kiyoji factory.

Precision equipment business (nano-microfabrication technology) was newly deployed.

Optical nano-printer "ImpFlex" was developed.

Small AC servo "Cuty Axis III" was developed.

Squid fishing machine "sanmei SX" was developed.

3-dimensional measuring device was developed by the application of precision control technology.

Parallel mechanic robot was developed.

Sep.: Para Robo Mini was developed. It got a great response at the national exhibition.

Dec.: Variations were added to small parallel robots.

Nanoimprint apparatus "ImpFlex-Essential" was developed.

It got a great response at the national exhibition together with Para Robo.

Si-super was developed.

New series of Si, high precision, vibration-free, perfect standstill "Si-super" was developed and started selling!

Scratches and foreign matter inspection equipment "IN-Spec Mashine" which can check completely with electron microscope.

Easy-to-use parallel link robot "ParaMotion" was developed and started selling!

"paraMotion" was upgraded to further evolution!

The NEW squid fishing machine [SX2] was developed.

For overseas markets and large fishing ship will select and use.

The hoisting power was upgrade.

Maintenance times ware less than [SH-H].

Wire tention control was so good.

The NEW squid fishing machine [Super SE-SX] was developed.

For JAPAN and the pacific ocean sea will be fitting.

[Typhoon7] was developed.

It was built with [Windows Embedded Compact7].

Sheet metal equipment was renewal.

Panching and laser equipment [LC-2512C1AJ]

Bending machine [HG-1003ATC]

[Si servo3] and [Si Link Unit] was developed.